Our Machines

Fengchi is a leading global manufacturer of post-press equipment; earning a global reputation by consistently designing, manufacturing, and marketing products that offer unmatched performance and technological advantages. Our team of experts is always available to help you find the right machinery for your needs.

Trusted by Industry Leaders Worldwide

Fengchi: The right supplier for your post-press processing

Fully automatic flute laminators, flip flop stackers, folder gluers, folder gluer stitchers, spot UV coating machines, and window patching machines – from Fengchi you get everything from a single source. Individually tailored to your printing and packaging production.

Discover a range of highly competitive equipment designed specifically for the needs of corrugated cardboard and folding carton manufacturers.

At Fengchi Printing Machinery, we guarantee our total support before, during, and after sale and installation. You will receive our technical support anytime, anywhere.

We’re at your disposal and we have the solutions to meet your print finishing requirements.

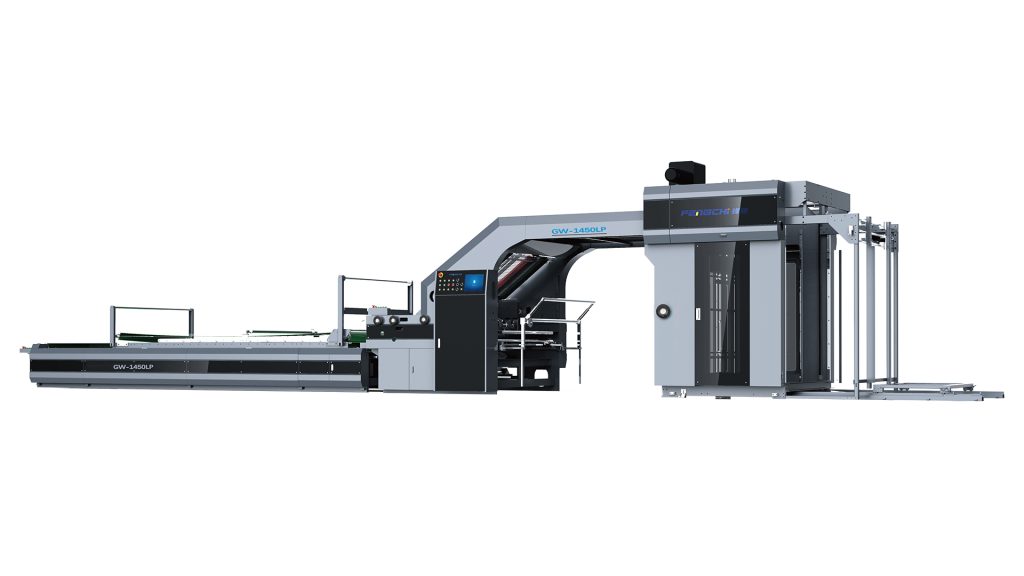

High Speed Flute Laminator Machines

Fengchi develops and manufactures high-speed flute laminators for corrugated packaging industries.

Key Features:

Max Speed: 22,000 sheets/hour.

Stable Production Speed: 16,000 sheets/hour (24/7 operation)

Fast Changeover: Quick setup in 2–5 minutes for different batch sizes.

Full Servo Control: Bus control system ensures high-speed, stable lamination with ±1.0mm accuracy.

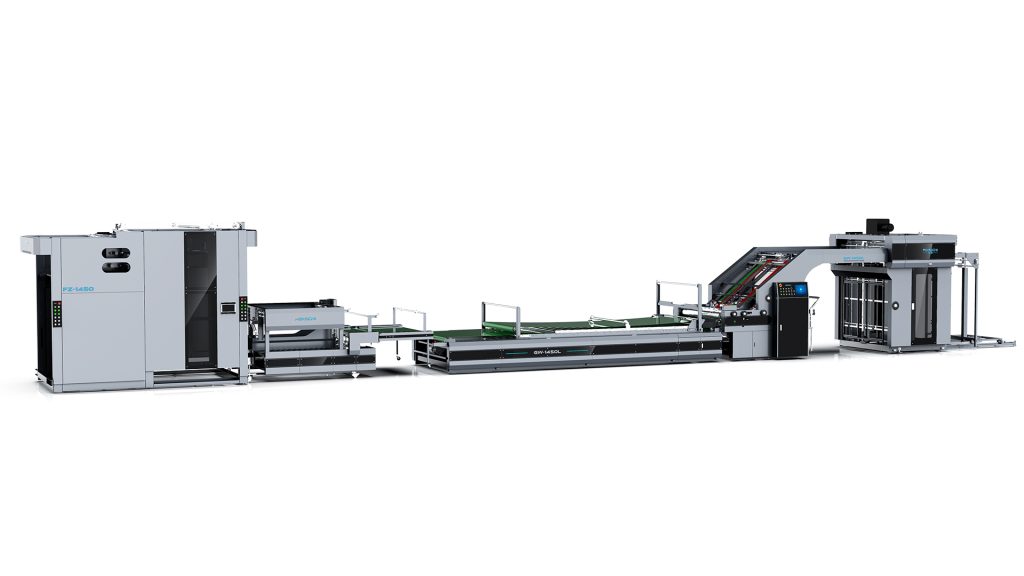

High Speed Flute Laminating Line

Our flute laminating line consists of a full servo high-speed flute laminator and a flip-flop stacker, helping corrugated packaging manufacturers improve efficiency and productivity.

Key Features:

12 servo motors with bus control for ultra-stable, precise operation.

Fully integrated laminating, turning, and paper collection.

Intelligent control system that maximizes laminating capacity.

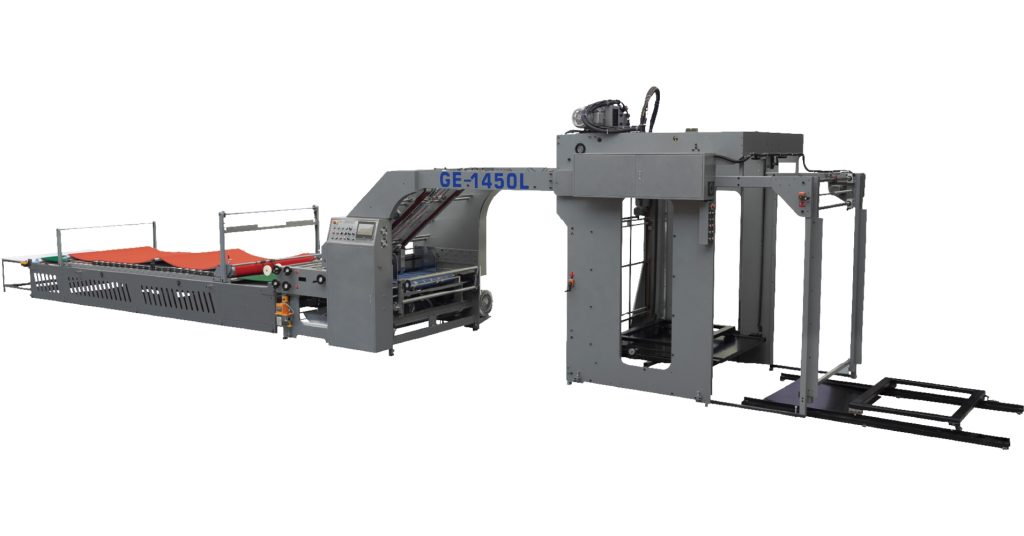

Automatic Flute Laminator Machines

Our automatic flute laminator simplifies corrugated cardboard production.

Key Features:

Stable Production Speed: 13,000 sheets/hour (153M/Min) (24/7 operation).

Laminating Accuracy: ±1.0mm standard sheet paper.

Minimized Order Change Time: 2-3 minutes.

Easy Operation: User-friendly controls minimize training and operator experience needed.

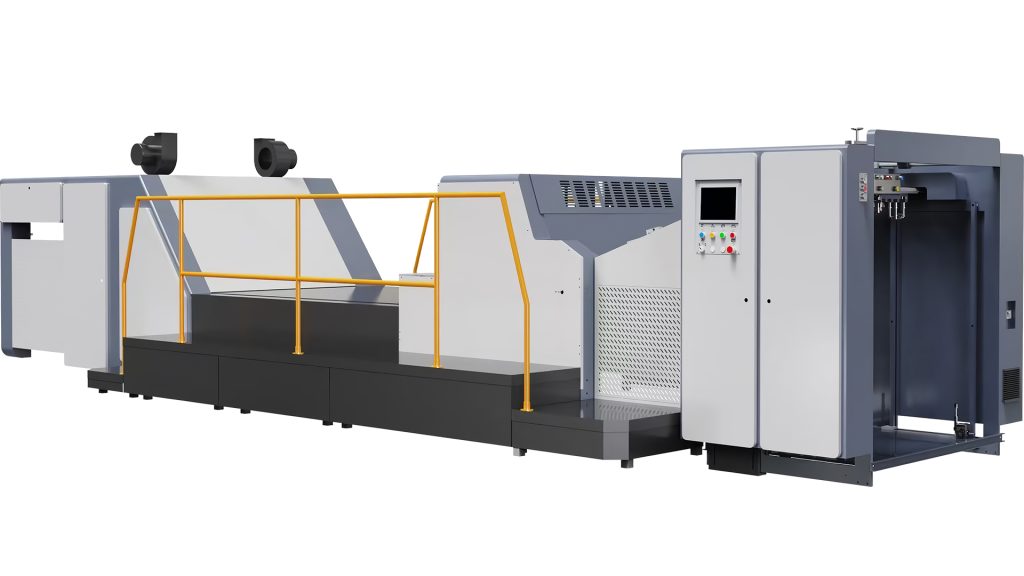

Automatic Cardboard Laminator Machines

Our automatic cardboard laminator powers high-volume packaging production for food, beverages, home appliances, toys, gifts, and cosmetics.

Key Features:

High Accuracy

Full-servo system with digital interface for ±0.5 mm laminating accuracy.

High Speed

Up to 10,000 sheets per hour—keep pace with your busiest workflows.

Full Servo Flip Flop Stacker Machines

Our full servo flip flop stacker is desianed to interconnect with high speed flute laminator as the automation of laminating production line.

Key Features:

Full servo control, barely any machine malfunction, no downtime.

High speed, stable speed 15000 sheets/hour; For thick paper, such as 5 layer corrugated board, speed can also reach 9000 sheets/hour.

Very low noise, machine running smoothly.

Suitable for different kinds of flute laminator.

Automatic Folder Gluer Machines

Our automatic folder gluers are engineered for the corrugated and cardboard box industry, delivering fast, reliable, and high‑volume box assembly.

Key Features:

Full servo control, full automatic, more accurate, more stable.

High speed, maximum speed 2,500 sheets/hour.

Job-change around 3-5 mins, with order memory function.

Automatic Folder Gluer Stitcher Machines

Boost your production with Fengchi’s automatic folder gluer stitcher machines. Designed for corrugated and folding carton manufacturers.

Key Features:

High Productivity: Speed Up to 1600 Stitches/Min

Single and double stitching modes with one-click switching.

Energy-saving swing head for faster, more stable stitching and improved box quality.

Versatility: Handle a wide range of carton sizes and materials.

TY Series Automatic Spot UV Coating Machines

Our automatic spot UV coating machine adds a precise, high-glossy finish to specific parts of your print, like logos, images or text, creating a strong contrast with matte or uncoated areas.

Key Features:

Works on thin and thick paper

Speeds up to 8,000 sheets per hour

Precise and clean coating

Focus Series Local UV Glazing Machine

Focus Series High Speed Local UV Glazing Machine adds a precise, high-glossy finish to specific parts of your print, like logos, images or text, creating a strong contrast with matte or uncoated areas.

Key Features:

Precision Spot UV Registration (±0.2mm tolerance)

Mechanical Velocity: 9000 sheets / hour

Quick Setup: 2-3 Minutes

Full Automation: One-Key Operation

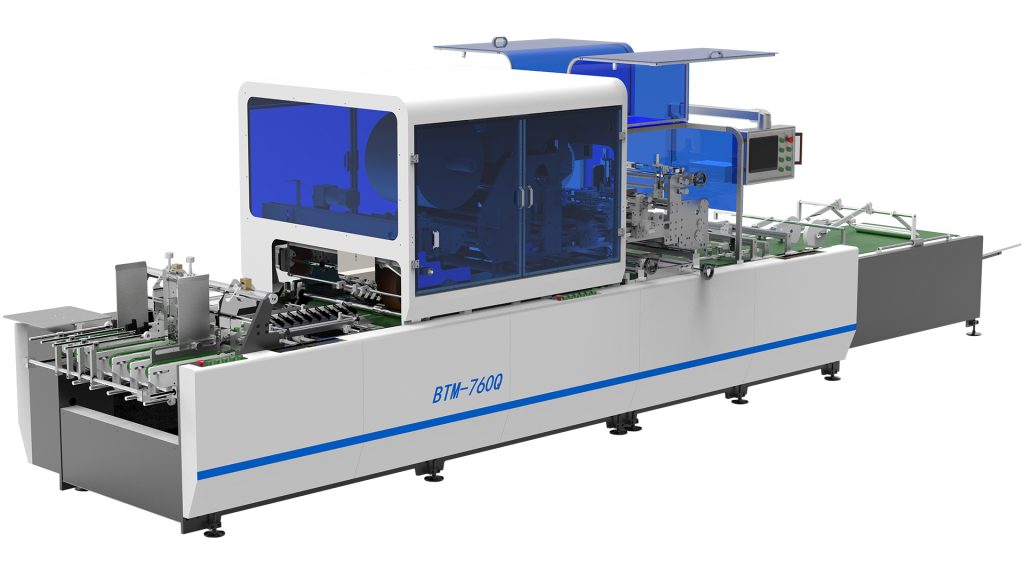

Model Q Window Patching Machines

Model Q Window Patching Machine has creasing and cornering function, and is specialized for variety window patterns.

Key Features:

Max speed 9,000 sheets/hr (155m/min), continuous 8,000 sheets/hr (138m/min), 24h non-stop.

±0.5 mm film accuracy. (full‑servo bus + proprietary tech).

Digital feed, glue‑position & film‑length settings.

Model P Window Patching Machines

Our Model P Window Patching Machines is engineered specifically for tissue box packaging and other flat window applications.

Key Features:

Max Speed: 36,000 sheets/hour

Positioning Accuracy: ±1.0 mm

9 Servo Motors for Smart Operation

Designed for 15+ Year Lifespan

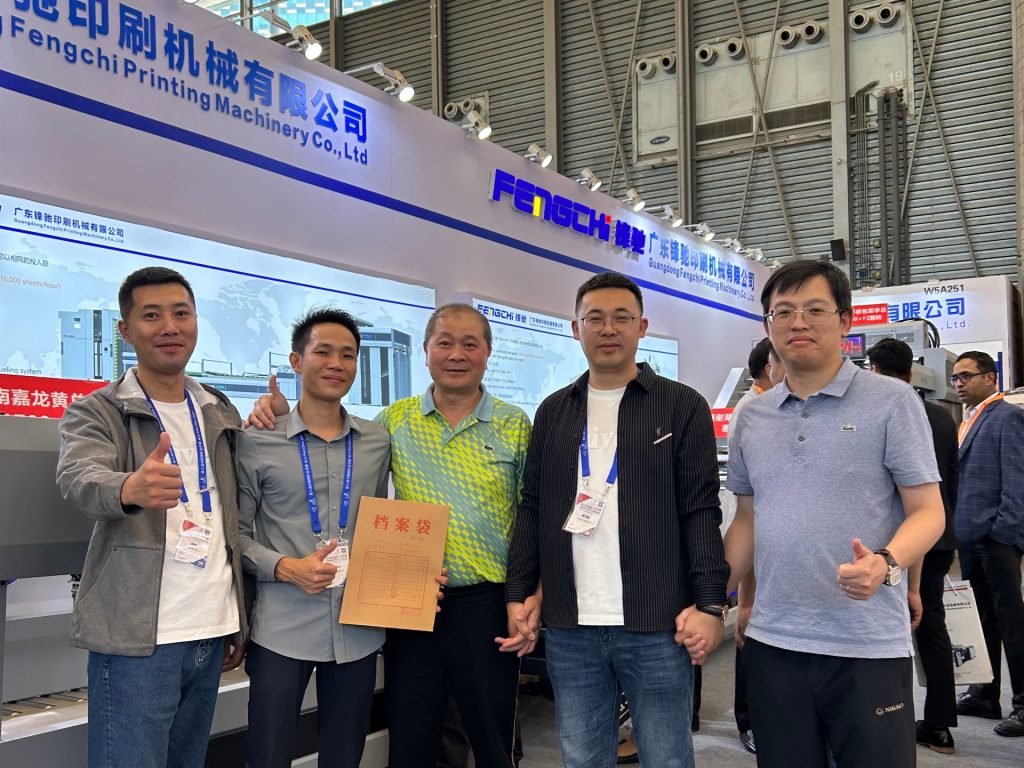

What Our Customers Say

See what our customers say about our post-press equipment.

We increased our corrugated board laminating throughput by 40% after installing the high-speed flute laminator. The support team was fantastic throughout the installation process.

– John Davidson, Production Manager

After trying three different brands, Fengchi equipment stands out for reliability. Minimal downtime and their service team responds immediately.

– Michael Torres, Operations Director

The window patching accuracy has eliminated our waste problems. We’re saving thousands annually on materials alone. Best investment we’ve made in years.

– Sarah Johnson, Owner

Why partner with Fengchi?

High Quality

Fengchi products are manufactured by a team of skilled and qualified technicians. Our quality management system is certified by ISO9001. Products manufactured by Fengchi are also certified by CE.

Innovative Solutions

We work with you to find not just one, but the right solution for your packaging production – from stand-alone to turnkey.

Global Support

With three offices around the world, and around 30 agents, we are able to provide local support on a global level.

Our service for your success

Fengchi Printing Machinery knows that successful installation, training, and support are critical to your operation and achieving the profitability gains you target. This drives our commitment to your success.

Our goal is to provide you with the tools and technical knowledge that your in-house maintenance needs, to be able to fix their own machines. Our technical support team and parts department work with customers to resolve issues over the phone, but when special care is needed, our team is prepared to make emergency field service visits, to get your plant up and running quickly. Parts, service, and support are handled directly through the Fengchi technical support group.

Ready To Boost Your Packaging Efficiency?

Join hundreds of satisfied customers who have increased their productivity with our equipment.