Automatic Cardboard

Laminator

The high-speed, precision automatic cardboard laminator that eliminates

manual errors, cuts labor costs, and scales your production effortlessly.

Automatic Cardboard

Laminator

Automatic cardboard laminator for packaging plants.

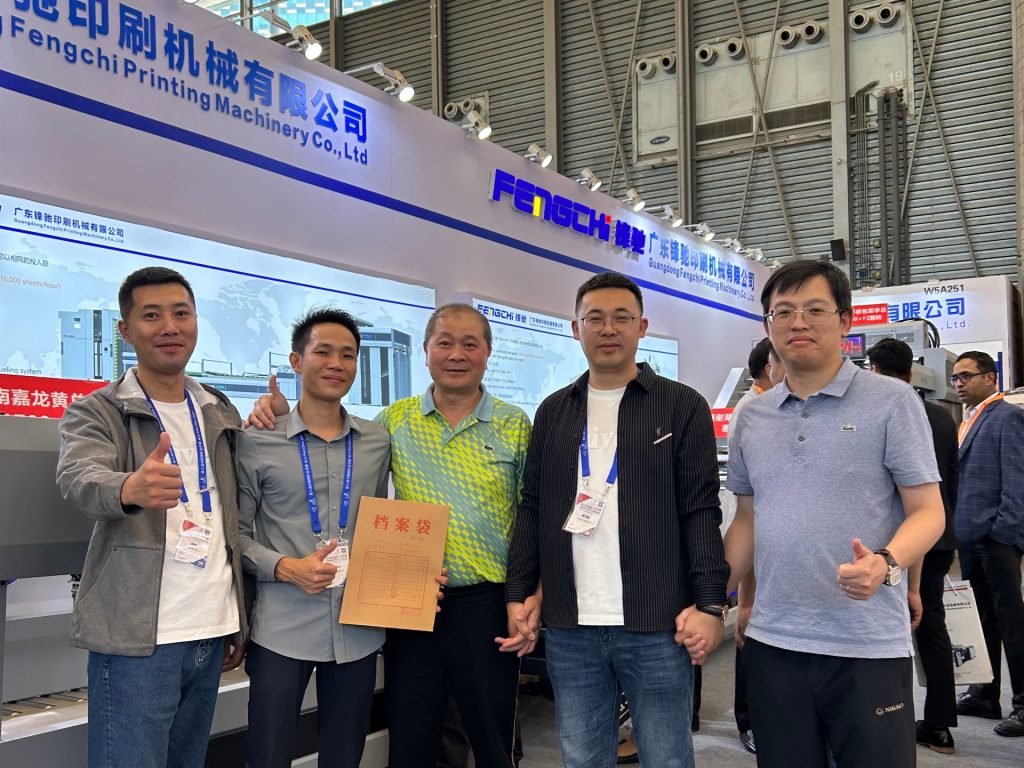

Trusted by Industry Leaders Worldwide

Main Features

Engineered for accuracy and speed, the GK Series delivers unparalleled performance in cardboard lamination.

High Speed

Maximum laminating speed can reach 10,000 sheets/hour.

High Accuracy

The full servo-controlled system with a digital operating system automatically adjusts the machine, laminating accuracy up to ± 0.5mm.

Wide Applicability

Using a front feeder suitable for the thinnest top paper 100gsm and thinnest

bottom paper 200gsm.

High Automation

One key operation by inputting paper size, automatic feeding of upper and bottom paper, and automatic paper collection after laminating.

Makeready Time: 2-5 minutes

Once paper size and thickness are input, all functions work automatically.

Glue-saving Design

High-precision stainless-steel core-wrapped glue roller accurately controls adhesive application at 18 g/m², significantly reducing glue consumption while ensuring bonding quality.

GK-1307 Automatic cardboard laminator

Model: GK-1307

Max Laminating Speed: 10000 sheets/hour

Generators Power: 3KW

Driven Type: Hydraulic

Speed Of Cover: 5-50 pieces/min

Laminating Accuracy: ±0.5mm

Watering Type: Automatic water

Power Consumption: 20kw

Machine Type: Cardboard Laminator

Machine Speed: 105 pcs/min

Max Paper Size: 1300mm * 720mm

Applicable Industries: Manufacturing Plant, Packing industry

Machinery Test Report: Provided

Weight Of Machine: 2500kg

Production Time: 70 days

GK-1310 Automatic cardboard laminator

Model: GK-1310

Max Laminating Speed: 7800 sheets/hour

Generators Power: 3KW

Driven Type: Hydraulic

Speed of Cover: 5-50 pieces/min

Laminating Accuracy: ±0.5mm

Watering Type: Automatic water

Power Consumption: 20kw

Machine Type: Cardboard Laminator

Machine Speed: 105 pcs/min

Max Paper Size: 1300mm * 1000mm

Applicable Industries: Manufacturing Plant, Packing industry

Machinery Test Report: Provided

Weight Of Machine: 2500kg

Production Time: 70 days

Automatic Cardboard Laminator

Product Gallery

Technical Data

| Model | GK-1307 | GK-1310 |

|---|---|---|

| Max. paper size (W x L) | 1300mm×720mm | 1300mm×1000mm |

| Min. paper size (W x L) | 500mm×350mm | |

| Top paper thickness | 100-700gsm | |

| Bottom paper thickness | 200-900gsm | |

| Max. Working Speed | 10000 Sheets/hour | 7800 Sheets/hour |

| Laminating Accuracy (W*L) | ±0.5mm (Standard Sheet Paper) | |

| Applicable Glue | Starch glue, resin glue, milky glue etc.,(PH value 6-8) | |

| Machine weight | 6500kg | |

| Machine size | 9900mm×2250mm×2180mm | |

| Input voltage | 380VAC/3P | |

| Power | 20kw | |

| Applicable paper | Thin paper, cardboard paper,coated paper,gray board,thick paperboard etc. | |

* This is the current configuration. It may be updated as technology evolves.

Our Service for Your Success

Fengchi Printing Machinery knows that successful installation, training, and support are critical to your operation and achieving the profitability gains you target. This drives our commitment to your success.

Our goal is to provide you with the tools and technical knowledge that your in-house maintenance needs, to be able to fix their own machines. Our technical support team and parts department work with customers to resolve issues over the phone, but when special care is needed, our team is prepared to make emergency field service visits, to get your plant up and running quickly. Parts, service, and support are handled directly through the Fengchi technical support group.

What Our Customers Say

See what our customers say about the GK Series automatic cardboard laminator.

“This cardboard laminator transformed our production line. We’ve seen a 40% increase in output and the consistency is unmatched. A game-changer.”

– John Doe, Production Manager

“The ROI was clear within the first 6 months. We reduced our laminating team from 4 people to 1, and the machine is far more reliable.”

– Jane Smith, Operations Director

Ready to upgrade Your Production?

Join hundreds of satisfied customers who have increased their productivity with our automatic cardboard laminators.