Automatic Flute

Laminator

Seamless, high-speed flute lamination – Automate your production line and

reduce labor costs while delivering flawless corrugated board every time.

Automatic Flute

Laminator

Automatic flute laminator engineered for corrugated cardboard production.

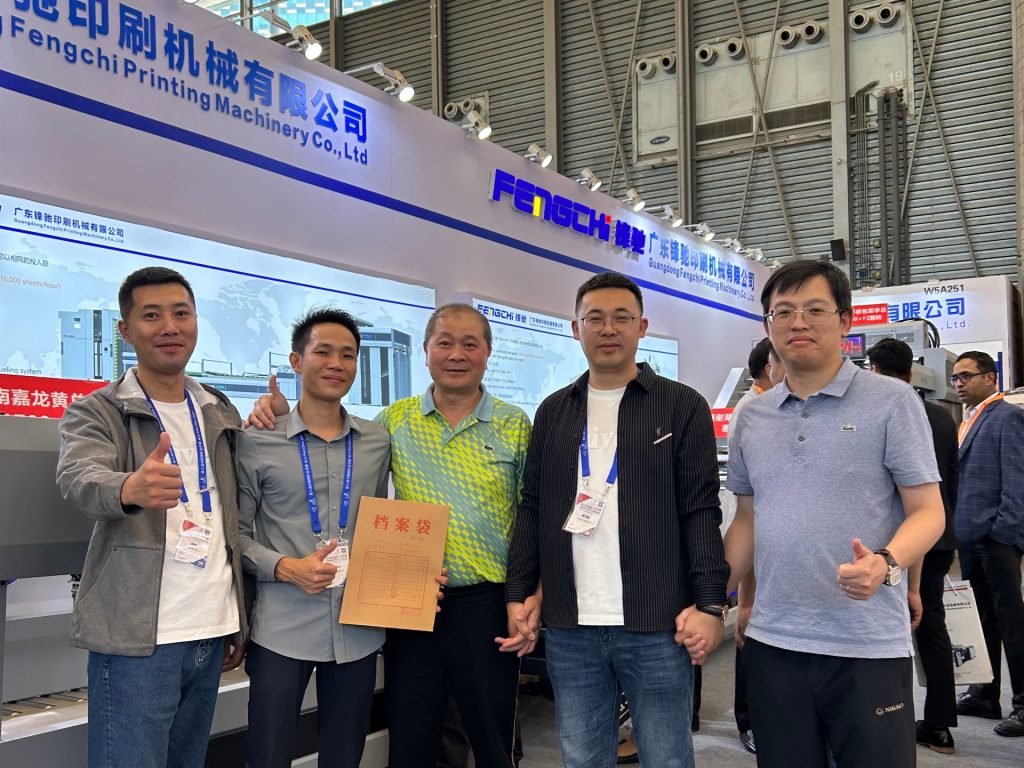

Trusted by Industry Leaders

How Our Automatic Flute Laminator Transforms Your Production

Engineered for precision, speed, and reliability to maximize your productivity and profitability.

High Throughput

Laminating speed: 153 m/min (13,000 sheets/hour).

Easy Operation

User-friendly controls minimize training and operator experience needed.

Easy Maintenance

Maintenance-free with auto-lubrication system.

Quick Changeover

Change over in 2–3 minutes for different batch sizes; boosts production efficiency.

Energy Efficient

Kinetic energy recovery system, save power, more economical.

Long Lifespan Design

Servo motors and drives built with 35% load reserve for 15+ years of consistent performance.

See our Automatic Flute Laminator in Action

Watch how our automatic flute laminator delivers flawless results with maximum efficiency

What Our Customers Say

Hear from industry leaders who have transformed their production with our automatic flute laminators

We’ve increased our daily output by 45% while reducing material waste. The ROI was achieved in just 10 months.

– John Smith, Production Manager

The technical support is exceptional. When we had a minor issue, their team resolved within 24 hours.

– Maria Johnson, Operations Director

The precision and consistency of the flute laminator have significantly improved our product quality.

– Robert Williams, CEO

GE-1450B Automatic flute laminator machine

Model: GE-1450B

Automatic Grade: Automatic

Performance: Adjustable

Patent: Patented Kinetic Energy Recovery System

Max. Speed: 13,000 sheets/hour

Advantages: Low Failure Rate, Safe, Efficiency, Long Life

After-sales Service: Maintenance-Free Automatic Refueling System

Warranty: Not specified.

GM-1450B Automatic flute laminator machine

Model: GM-1450B

Automatic Grade: Automatic

Performance: Adjustable

Patent: Patented Kinetic Energy Recovery System

Max. Speed: 10,000 sheets/hour

Advantages: Low Failure Rate, Safe, Efficiency, Long Life

After-sales Service: Maintenance-Free Automatic Refueling System

Warranty: Not specified.

Automatic Flute Laminator

Product Gallery

2.Whole pallet loading: adopt the whole pallet loading design to save the manpower and time. After the pallet is loaded against the gear gauge, aligning the zero position to make left and right adjustment

3.Separate manual stacking: when the platform descend, manual stack the paper on the pallet

2.10 limits and protective sensors, real-time detection and adjustment to ensure safety production

3.Industry Initiative of servo control lifting platform, single sheet lifting same as offset printing press, without wear, and can be set as from 1~50 sheet/lifting.

2.the correction system of paper feeding ensure the high speed feeding smoothly without any skew

3.The sheet delivery stopper make sure the single sheet feeding, optional to upgrade by adding double sheet detection system

4.Becker vacuum pump with large suction, strong blowing, good stability and durable

1) Industry Initiative of leading edge bottom feeder, suitable for a variety of warped deformation, rough and heavy bottom board feeding 2)Unidirectional rotation feeding roller, without wear, life cycle up to 10 years 3)Standard equipped with right cylinder to pile up the paper in neat, available to adjust in a whole or on the right side, greatly saving manpower. 4)Patented non-stop suction with 5.5KW power, air flow adjustable at will

2.Belt bottom feeder,Extra heavy wear-resistant belt, suitable for cardboard/flute laminating, without scratch in conveying

Technical Data

| Model | GE-1450B | GE-1450BP | GM-1450B |

|---|---|---|---|

| Max. paper size (W x L) | 1450mm * 1450mm | ||

| Min. paper size (W x L) | 360mm * 360mm | ||

| Bottom Paper Sheet Thickness | 300gsm – 10mm | 0.3–7 mm | |

| Upper paper weight | 150gsm – 700gsm | ||

| Max. Working Speed | 13,000 sheets/hour (153 m/min) (Depends on paper quality) | 10,000 sheets/hour (150 m/min) | |

| Laminating Accuracy (W*L) | ±1.0mm (Standard Sheet Paper) | ±1.5 mm (standard flatboard) | |

| Applicable Glue | Resin adhesive, starch glue and etc (PH6~8 will be suitable) |

PVA (white glue), starch adhesives, etc. (recommended pH 6–8) | |

| Power Supply | 380VAC/3P | ||

| Power | 20KW | ||

| Kinetic energy recovery system | — | — | 4.4 kW regenerative system — recovers over 3 kWh of electrical energy per hour |

| Applicable substrates | A, B, C, E, F, 3ply, 5ply corrugated board, and cardboard within above mentioned range | A, B, E, F flutes, double-flute and other flat corrugated boards; cardboard ≥ 300 gsm for lamination. | |

| Machine weight | 7000KG | 7000KG | 6500KG |

| Overall dimension (L*W*H) | 15400mm * 2300mm * 2550mm | 11500mm * 2300mm* 2550mm | |

* This is the current configuration. It may be updated as technology evolves.

First Class Service & Support

Fengchi Printing Machinery knows that successful installation, training, and support are critical to your operation and achieving the profitability gains you target. This drives our commitment to your success.

Our goal is to provide you with the tools and technical knowledge that your in-house maintenance needs, to be able to fix their own machines. Our technical support team and parts department work with customers to resolve issues over the phone, but when special care is needed, our team is prepared to make emergency field service visits, to get your plant up and running quickly. Parts, service, and support are handled directly through the Fengchi technical support group.

Ready to Transform Your Production Line?

Join hundreds of industry leaders who have boosted their productivity and profitability with our automatic flute laminators.