GW Series Flute

Laminator

Precision corrugated board laminating at 22,000 sheets/hour with industry-leading reliability.

Reduce waste & labor costs while increasing productivity.

GW Series Flute

Laminator

High-speed flute laminator for corrugated and cardboard packaging.

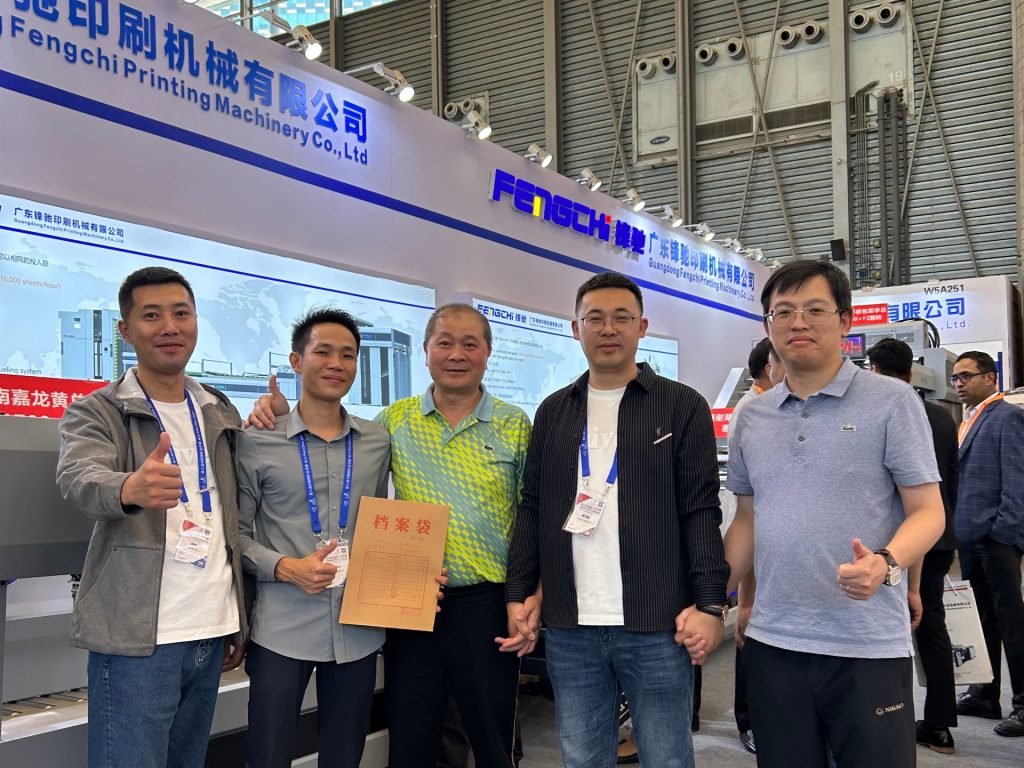

Trusted by Industry Leaders Worldwide

Engineered for Maximum Performance

Our full-servo high-speed flute laminator delivers tangible results that impact your bottom line

50% Higher Output

Increase production speed up to 180m/min with precision servo technology

20% Less Waste

Advanced registration control minimizes material waste and improves efficiency

30% Labor Savings

Automated features reduce manual intervention and operator requirements

See Our Machine in Action

Watch how our full servo high-speed automatic flute laminator delivers precision performance

Applications

Main Features

High Throughput

Max speed 22,000 sheets/hr with continuous operation at 16,000 sheets/hr for 24/7 production.

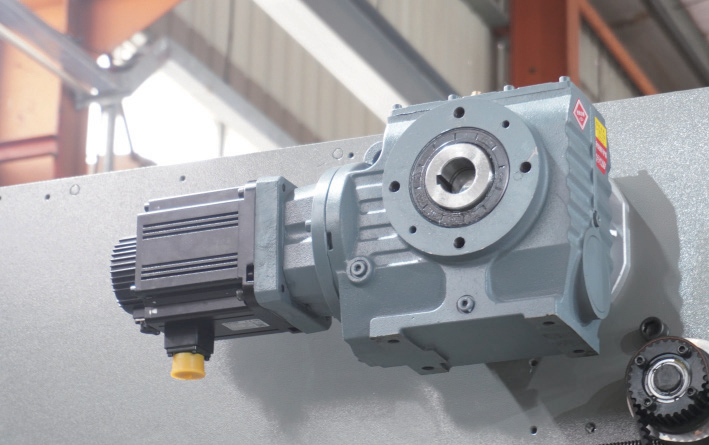

Fully Servo Driven

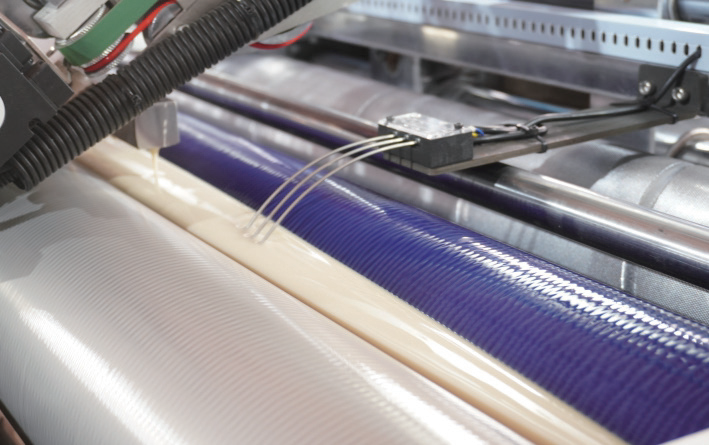

Full-servo motion control for precise alignment and consistent lamination quality

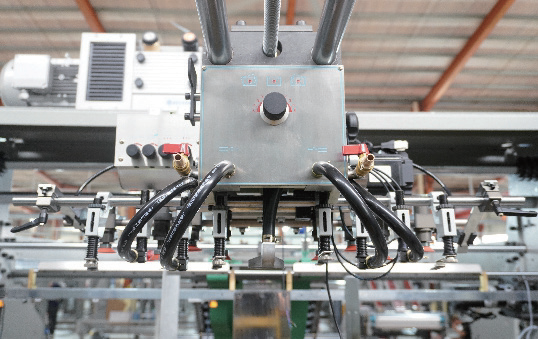

Precise Glue Application

150mm stainless steel roller, laser-engraved anilox roller applies glue evenly at just 18g/m² – 30% glue savings, no splashing, clean finish.

Fast Job Changeover

Quick setup in 2–5 minutes for different batch sizes; boosts production efficiency.

Energy Efficient

Consumes only 8kW/hour – saves up to 20% on power.

Long Lifespan Design

Servo motors and drives built with 35% load reserve for 15+ years of consistent performance.

High Speed Flute Laminators We Offer

At Fengchi Printing Machinery, we offer a wide range of high-speed flute laminators to meet your production needs.

GW-1450L Flute Laminator

Model: GW-1450L

Membrane Material: Paper

Plastic Film Mulching Modes: Hot Laminating

Performance: Anticorrosive

Patent: Leading Edge Paper Feeding Patent

Stable Speed: 16,000 Sheets/Hour

Features: Fully Automatic, Intelligent, User-Friendly Design

Feeding Mechanism Features: Unique Servo Vacuum Paper Feeding

Advantages: Low Failure Rate, High Efficiency, Long Life

Transport Package: Standard Package

Specification: 16300mm * 2400mm * 2550mm

Trademark: Fengchi

Origin: China

After-sales Service: Engineers Available Video & Video conference Remote

Warranty: 1 Year

Classification: Post-Coating Laminating Machine

Application: Packaging Paper, Color Printing, Cardboard and Corrugated Laminating

Driven Type: Mechanical

Automatic Grade: Automatic

Customization: Available

GW-1700L Flute Laminator

Model: GW-1700L

Membrane Material: Paper

Plastic Film Mulching Modes: Hot Laminating

Performance: Anticorrosive

Patent: Leading Edge Paper Feeding Patent

Stable Speed: 16,000 Sheets/Hour

Features: Fully Automatic, Intelligent, User-Friendly Design

Feeding Mechanism Features: Unique Servo Vacuum Paper Feeding

Advantages: Low Failure Rate, High Efficiency, Long Life

Transport Package: Standard Package

Specification: 17300mm * 2400mm * 2650mm

Trademark: Fengchi

Origin: China

After-sales Service: Engineers Available Video & Videoconference Remote

Warranty: 1 Year

Classification: Post-Coating Laminating Machine

Application: Packaging Paper, Color Printing, Cardboard and Corrugated Laminating

Driven Type: Mechanical

Automatic Grade: Automatic

Customization: Available

GW-2200L Flute Laminator

Model: GW-2200L

Membrane Material: Paper

Plastic Film Mulching Modes: Hot Laminating

Performance: Anticorrosive

Patent: Leading Edge Paper Feeding Patent

Stable Speed: 16,000 Sheets/Hour

Features: Fully Automatic, Intelligent, User-Friendly Design

Feeding Mechanism Features: Unique Servo Vacuum Paper Feeding

Advantages: Low Failure Rate, High Efficiency, Long Life

Transport Package: Standard Package

Specification: 18500mm * 3050mm * 2880mm

Trademark: Fengchi

Origin: China

After-sales Service: Engineers Available Video & Videoconference Remote

Warranty: 1 Year

Classification: Post-Coating Laminating Machine

Application: Packaging Paper, Color Printing, Cardboard and Corrugated Laminating

Driven Type: Mechanical

Automatic Grade: Automatic

Customization: Available

GW-1450LP Flute Laminator

Model: GW-1450LP

Automatic Grade: Automatic

Membrane Material: Paper

Performance: Anticorrosive

Patent: Leading Edge Paper Feeding Patent

Stable Speed: 16,000 Sheets/Hour

Advantages: Low Failure Rate, High Efficiency, Long Life

After-sales Service: Engineers Available Video & Videoconference Remote

Warranty: 1 Year

GW-1700LP Flute Laminator

Model: GW-1700LP

Automatic Grade: Automatic

Membrane Material: Paper

Performance: Anticorrosive

Patent: Leading Edge Paper Feeding Patent

Stable Speed: 16,000 Sheets/Hour

Advantages: Low Failure Rate, High Efficiency, Long Life

After-sales Service: Engineers Available Video & Videoconference Remote

Warranty: 1 Year

GW-2200LP Flute Laminator

Model: GW-2200LP

Automatic Grade: Automatic

Membrane Material: Paper

Performance: Anticorrosive

Patent: Leading Edge Paper Feeding Patent

Stable Speed: 16,000 Sheets/Hour

Advantages: Low Failure Rate, High Efficiency, Long Life

After-sales Service: Engineers Available Video & Videoconference Remote

Warranty: 1 Year

GW-1100BP Flute Laminator

Model: GW-1100BP

Membrane Material: Paper

Performance: Anticorrosive

Max Speed: 15,000 Sheets/Hour

Features: Fully Automatic, Intelligent, User-Friendly Design

Feeding Mechanism Features: Unique Servo Vacuum Paper Feeding

Advantages: Low Failure Rate, High Efficiency, Long Life

Transport Package: Standard Package

Specification: 13600mm * 2000mm * 2550mm

Trademark: Fengchi

Origin: China

After-sales Service: Engineers Available Video & Video conference Remote

Warranty: 1 Year

Application: Packaging Paper, Color Printing, Cardboard and Corrugated Laminating

Driven Type: Mechanical

Automatic Grade: Automatic

Customization: Available

GW-1450BP Flute Laminator

Model: GW-1450BP

Automatic Grade: Automatic

Membrane Material: Paper

Performance: Anticorrosive

Patent: Leading Edge Paper Feeding Patent

Stable Speed: 16,000 Sheets/Hour

Advantages: Low Failure Rate, High Efficiency, Long Life

After-sales Service: Engineers Available Video & Videoconference Remote

Warranty: 1 Year

GW-1700BP Flute Laminator

Model: GW-1700BP

Automatic Grade: Automatic

Membrane Material: Paper

Performance: Anticorrosive

Patent: Leading Edge Paper Feeding Patent

Stable Speed: 16,000 Sheets/Hour

Advantages: Low Failure Rate, High Efficiency, Long Life

After-sales Service: Engineers Available Video & Videoconference Remote

Warranty: 1 Year

GW-2200BP Flute Laminator

Model: GW-2200BP

Automatic Grade: Automatic

Membrane Material: Paper

Performance: Anticorrosive

Patent: Leading Edge Paper Feeding Patent

Stable Speed: 16,000 Sheets/Hour

Advantages: Low Failure Rate, High Efficiency, Long Life

After-sales Service: Engineers Available Video & Videoconference Remote

Warranty: 1 Year

Product Gallery

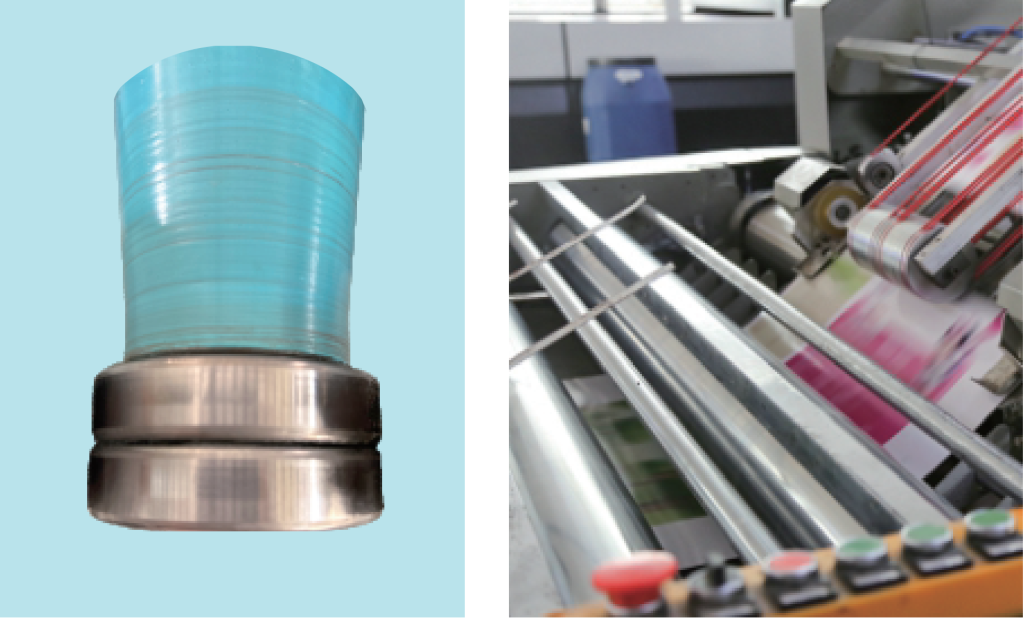

PU Bottom Feeding Wheel

- Unidirectional rotating feeding roller, without wear and tear, service life cycle up to 10 years.

Leading-edge Feed System

- Self-developed leading-edge feed system specially for deformed, warped corrugated papers.

One-button Operation

- Adopting 7-8 servo motors control systems, digital intelligent input, automatic order changeover in 2-3 min.

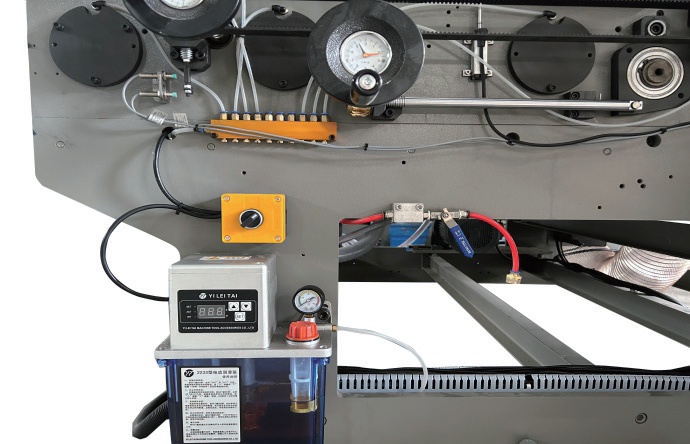

Automatic Lubrication of Bearings

- Intelligent control for automatic lubrication, no need for daily maintenance, saving labor costs, and improving production efficiency.

Enlarged Glue Roller

- Enlarged 150mm diameter stainless steel roller, laser engraved anilox, high-speed and stable without glue splashing.

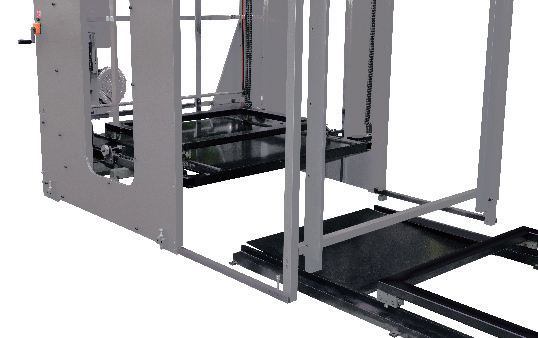

Servo Control Lifting Pile Plate

- High speed feeder smooth feeding, single sheet lifting same as offset printing press, high efficient and stable.

Dual-bearing Structure

- Ensures efficient and stable operation of the machine with doubled life cycle.

Pre-stacking System

- Whole pallet loading platform, saving labor costs and time.

Shaft-less High Speed Feeder

- Servo controlled high-speed shaft-less feeder front-and-rear auto-adjustment.

Technical Information

Leading edge feeder version:

| Model | GW-1450L | GW-1450LP | GW-1700L | GW-1700LP | GW-2200L | GW-2200LP |

|---|---|---|---|---|---|---|

| Max. paper size (W x L) | 1450mm * 1450mm | 1700mm * 1650mm | 2200mm * 2100mm | |||

| Min. paper size (W x L) | 360mm * 360mm | 360mm * 360mm | 450mm * 380mm | |||

| Bottom Paper Sheet Thickness | F flute-10mm | |||||

| Upper Paper Sheet Thickness (W*L) | 120 g-700 g | |||||

| Max. Working Speed | 22,000 Sheets/Hour (175 M/Min) | |||||

| Laminating Accuracy (W*L) | ±1.0mm (Standard Sheet Paper) | |||||

| Applicable Glue | Resin adhesive, starch glue and etc (PH6~8 will be suitable) |

|||||

| Power Supply | 380VAC/3P | |||||

| Power | 26KW | 30KW | 32KW | |||

| Applicable Corrugated Board | A, B, C, E, F, 3ply, 5ply, 7ply corrugated board, and cardboard within above mentioned thickness range | |||||

| Machine weight | 8000KG | 8500KG | 9000KG | |||

| Overall dimension (L*W*H) | 15700mm * 2400mm * 2550mm | 16300mm * 2650mm * 2550mm | 18500mm * 3050mm* 2880mm | |||

* This is the current configuration. It may be updated as technology evolves.

Technical Information

Belt feeder version:

| Model | GW-1450B | GW-1450BP | GW-1700B | GW-1700BP | GW-2200B | GW-2200BP |

|---|---|---|---|---|---|---|

| Max. paper size (W x L) | 1450mm * 1450mm | 1700mm * 1650mm | 2200mm * 2100mm | |||

| Min. paper size (W x L) | 360mm * 360mm | 360mm * 360mm | 450mm * 380mm | |||

| Bottom Paper Sheet Thickness | 300gsm - 10mm | |||||

| Upper Paper Sheet Thickness (W*L) | 120 g-700 g | |||||

| Max. Working Speed | 22,000 Sheets/Hour (175 M/Min) | |||||

| Laminating Accuracy (W*L) | ±1.0mm (Standard Sheet Paper) | |||||

| Applicable Glue | Resin adhesive, starch glue and etc (PH6~8 will be suitable) |

|||||

| Power Supply | 380VAC/3P | |||||

| Power | 26KW | 30KW | 32KW | |||

| Applicable Corrugated Board | Cardboard above 300gsm, and A, B, C, E, F, 3ply, 5ply corrugated board | |||||

| Machine weight | 8000KG | 8500KG | 9000KG | |||

| Overall dimension (L*W*H) | 15700mm * 2400mm * 2550mm | 16300mm * 2650mm * 2550mm | 18500mm * 3050mm* 2880mm | |||

* This is the current configuration. It may be updated as technology evolves.

Why Choose Fengchi?

If you are looking for a reliable and fully automatic high-speed flute laminator, Fengchi is the right supplier for you.

Increase Productivity

By automating your corrugated laminating process, we deliver an accurate and consistent lamination, reducing waste and minimizing downtime.

15+ Years of Experience

More than 15 years of experience within automation gives us an enormous know-how and expertise in laminating solutions.

Reliable Solutions

We deliver reliable and easy-to-operate solutions of high quality that help our customers optimize their packaging line.

Installations worldwide

We proudly export corrugated laminating solutions worldwide, ensuring international clients benefit from our innovative technology.

Our Service for Your Success

Our service team ensures maximum production reliability and efficiency.

From mechanical and electrical assembly to performance calibration and operator training, our specialists ensure every piece of technology works flawlessly from day one. And with aftermarket support built on responsiveness and expertise, your uptime becomes our priority.

Whether you need parts, maintenance or digital remote support, we are here for you: sales@laminatorfc.com

What Our Customers Say

Hear from industry leaders who have transformed their production with our automatic flute laminators

We are extremely pleased and proud to have acquired the top laminator for flute in China from fengchi. It‘s an exciting milestone for us to have the best in the industny. I also want to extend my gralude for the exceplional senitce and smoolh negoialion process weve experienced. Congralulalions to both our teams for this achievemen!

– JULIO Julio Miamau, CEO

We have partnered with this company for years and have never been disappointed. Both the product quality and responsiveness of their service are outstanding. Every delivery meets our high standards, giving us a competitive edge in the market. They are truly a trustworthy partner.

– Farhan Mathur, Operations Director

The Turkey customer’s operator likes the FENGCHI machine very much. He said it’s easy to operate, and the finished products are very good.

– Haluk Önder, Operator

Frequently Asked Questions

Get answers to common questions about our full servo high-speed automatic flute laminator

Why choose us to cooperate?

1. “FENGCHI” is well-known brand and paper flute laminator master in China since 2009, focus on solving the manufacturing process of over-gluing and laminating & stacking after the post-printing of color cardboard & corrugated cartons.

2. Strong R&D team by 25 senior engineers over 30 years experience in printing industry. With 30 patents to ensure product more stable, more efficient and durable.

3. After-sale service and technical assistance: company provides after sales service and technical assistance as per customers’ requirement and needs with response within 24 hours.

4.Cost saving: Full servo digital operating system greatly reduce operator level(normally two primary operator) with manpower saving, 150mm roller with double bearing and auto refueling system make equipment durable and free maintenance. China highest laminating speed at 22,000pcs/hour.

Are you a manufacturer?

Yes, we are Flute Laminator Master from China over 15 years, specialize in automatic flute laminators and flip flop stackers.

Do you have stock products to sell?

We produce machines in bacth normally. So most models we have some in stock, please check with us before ordering.

How about warranty?

Warranty period: 12 months from the shipping date of machine. Warranty will be not valid if machine subject to misuse or accidental damage or operator’s error. During the valid time, we will supply spare parts. If you have any other questions, pls contact us and we will reply you through product’s photos and videos to make every detail clear. We also provide all lifetime warranty with paid service.

How about installation and training?

Normally, one operator can finish intallation in 2 hours with installation manual and video. If purchaser’s engineer travels at own cost to China, free training session. If engineer sent to purchaser’s factory, all travel cost paid by purchaser.

Do you test all your goods before delivery?

Yes, we have 100% functional testing and pilot run before delivery to ensure product integrity. All products are certificed by CE.

What is your delivery time?

Our delivery time is 10-30 working days after receiving full payment or deposit. The specific delivery time depends on the product and the order quantity.

What are your packaging conditions?

Usually, we pack the machine in a container with a plastic bag with desiccants, then with strong seaworthy wooden cases. Each machine will be protected by anti-rusted oil before put into case.

Will you supply for OEM orders?

Yes, we can customize the production machine according to your requirements.

Ready to Transform Your Production?

Join 1000+ packaging companies that have increased their output and profitability with our high-speed flute laminators