TY Series Spot UV

Coating Machine

Adds a precise, high-glossy finish to specific parts of your print.

Up to 6500-8000 sheets/hour. Coating Accuracy: ±0.15mm

TY Series Spot UV

Coating Machine

Up to 6500-8000 sheets/hour. Coating Accuracy: ±0.15mm

Machine Overview

Fengchi is a leading global manufacturer of automatic spot UV coating machines.

TY Series Automatic Spot UV Coating Machine adds a precise, high-glossy finish to specific parts of your print, like logos, images or text, creating a strong contrast with matte or uncoated areas.

We guarantee our total support, before, during and after sale and installation.

Key Benefits:

- Speeds up to 8,000 sheets per hour

- Coating Registration Accuracy: ±0.15mm

- Coating Layer Thickness: 0.15mm ~0.60mm

- Full Automation: One-Key Operation

- Quick Setup: 2-3 Minutes

Contact our experts to discuss your project or get a quote.

See It in Action

Technical Data

| Model | TY-1060W | TY-1060W-L | TY-1460W | TY-1650W |

|---|---|---|---|---|

| Max.Sheet Size(L * W) | 750mm×1060mm | 1100mm×1460mm | 1300mm×1650mm | |

| Min.Sheet Size (L * W) | 310mm×406mm | 350mm×460mm | 350mm×460mm | |

| Max.Coating Area (L * W) | 730mm×1040mm | 1090mm×1440mm | 1290mm×1640mm | |

| Coating Registration Accuracy | ±0.15mm | |||

| Coating Layer Thickness | 0.15mm ~0.60mm | |||

| Sheet Thickness | 80 ~ 500 gsm | 105 ~ 600 gsm | 120 ~600 gsm | |

| Up to | 6500-8000 sheets/hour | Up to 5-6000 sheets/hour | Up to 4-5000 sheets/hour | |

| Power Required | 40kw (W water-based) | 44kw (E oil-based) | 68kw/Water-based: oil-based total power | 76kw/Water-based: oil-based total power |

| Machine Dimension | 10625mm×2260mm×2100mm | 13225mm×2260mm×2100mm | 11800mm×3400mm×2300 mm | 12840mm×3400mm×2360 mm |

| Machine Weight | 7600kg | 8200kg | 10200kg | 12000kg |

* This is the current configuration. It may be updated as technology evolves.

Product Gallery

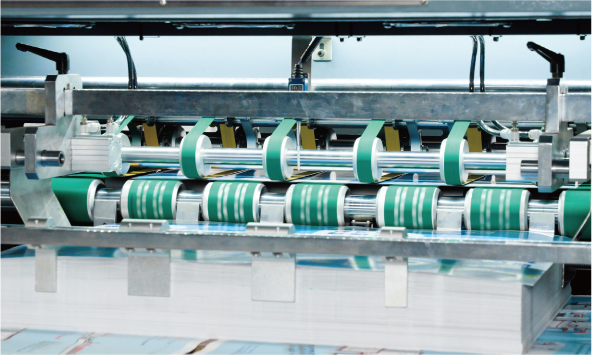

Multi-functional Coating Oil Head

- Dual-roller differential-speed coating head ensures flat, uniform, and glossy oil film with precision. Optional ceramic anilox roller with chambered doctor blade configuration.

Electrical Control System

- Full-machine variable frequency drive (VFD) with PLC programmable controller ensures high stability and low failure rate.

Automatic Paper Collector

- Integrated auto-loading platform with maximum stack height of 1,200mm.

- Photoelectric pneumatic dual-side alignment system for precise stacking.

- Thin-paper guiding device guarantees smooth and orderly sheet delivery.

Paper Feeding and Printing Unit

- Swing-arm sheet transfer mechanism supports maximum speed of 8,000 sheets/hour. Impression and coating cylinders undergo precision grinding and dynamic balancing calibration for dimensional accuracy. Quick-mount system for coating cylinder blankets and plate bases, enabling fast plate changes.

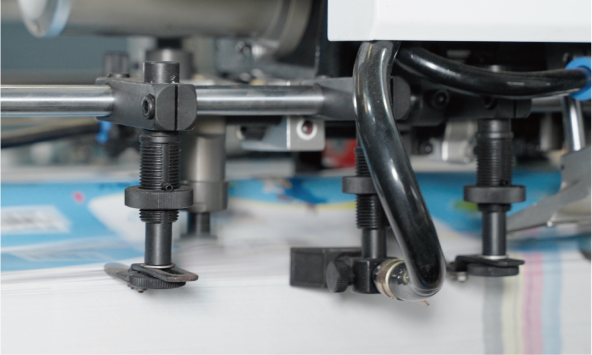

Automatic Paper Feeder

- High-reliability suction heads with linear slide rails ensure fast paper feeding, tightly delivering sheets of all sizes.

- Sensitive electro-mechanical double-sheet detector automatically stops feeding upon detecting multiple sheets.

- Maximum paper stack height: 1,150mm.

- Precision front and side guides (front guide and pull guide) with quick-adjust mechanisms for accurate positioning.

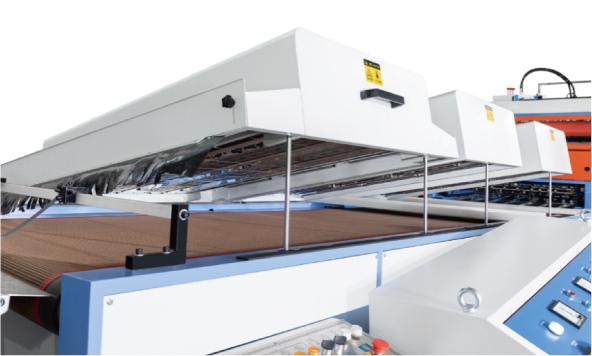

UV Drying and Curing Equipment

- Three UV mercury lamps ensure rapid UV coating curing.

- Teflon mesh conveyor with bottom suction enables quiet, high- speed curing and maintenance ease.

- Full/half-lamp switching and UV leakage protection enhance safety.

- Integrated auto-temperature control, fault trip, and cooling/exhaust systems prevent overheating.

- Dual IR drying groups (12×1kW lamps, staggered layout).

- Auxiliary air-blowing guarantees uniform heat distribution.

Why Partner with Fengchi?

Increase Productivity

By automating your corrugated laminating process, we deliver an accurate and consistent lamination, reducing waste and minimizing downtime.

15+ Years of Experience

More than 15 years of experience within automation gives us an enormous know-how and expertise in laminating solutions.

Reliable Solutions

We deliver reliable and easy-to-operate solutions of high quality that help our customers optimize their packaging line.

Installations worldwide

We proudly export corrugated laminating solutions worldwide, ensuring international clients benefit from our innovative technology.

First Class Service & Support

Fengchi Printing Machinery knows that successful installation, training, and support are critical to your operation and achieving the profitability gains you target. This drives our commitment to your success.

Our goal is to provide you with the tools and technical knowledge that your in-house maintenance needs, to be able to fix their own machines. Our technical support team and parts department work with customers to resolve issues over the phone, but when special care is needed, our team is prepared to make emergency field service visits, to get your plant up and running quickly. Parts, service, and support are handled directly through the Fengchi technical support group.

Ready to Enhance Your Production Efficiency?

Request a quote or schedule a demo to see the TY Series in action.