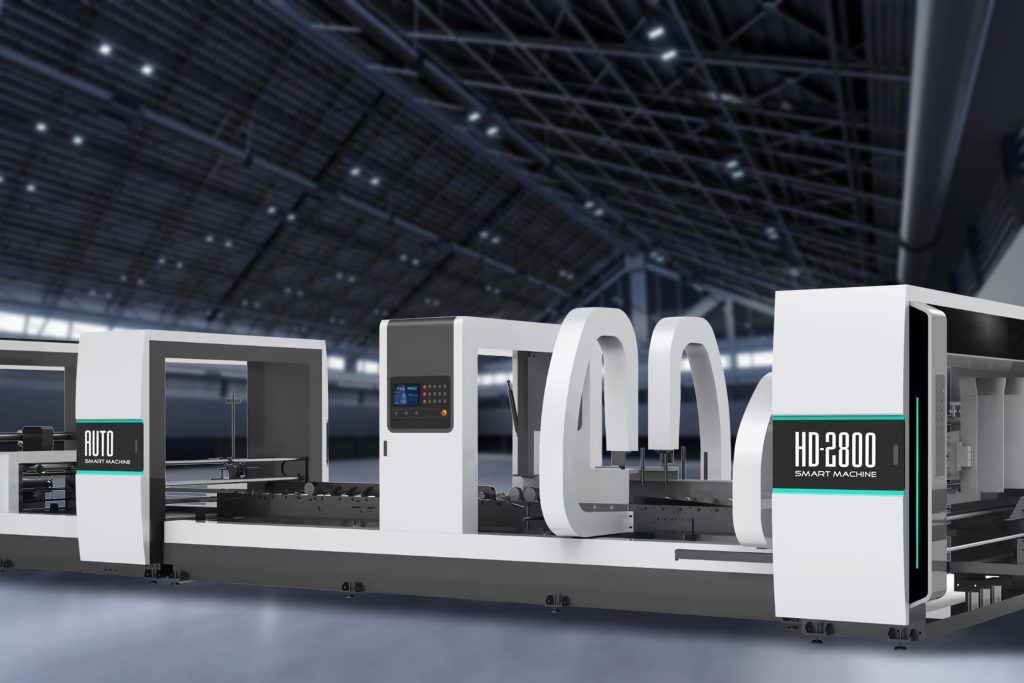

HD Series Automatic

Folder Gluer Stitcher

High-speed folder gluer stitcher for corrugated boxes.

Up to 1600 stitches/min · Max sheet 3600 × 1600 mm · 3–5 min job changeover.

HD Series Folder

Gluer Stitcher

1600 Stitches/Min. Max Sheet 3600 mm × 1600mm

Machine Overview

High Speed Folder Gluer Stitcher

Fengchi is a leading global manufacturer of automatic folder gluer and stitchers.

Since 2009, Fengchi has led the industry in folding gluing and stitching technology, delivering reliable, high‑quality equipment built for maximum uptime. They are ideal for packaging manufacturers producing high volumes of corrugated boxes.

We guarantee our total support, before, during and after sale and installation.

Key Benefits:

- Up to 1600 Stitches/Min

- Max Sheet 3600mm × 1600mm

- Job Changeover 3–5 Minute

- Operator Friendly

Contact our experts to discuss your project or get a quote.

See the HD Series — High-Speed Folder Gluer & Stitcher in Action

Watch how our high-speed folder gluer and stitcher transforms corrugated box production with precision and efficiency.

Main Features

Engineered for precision and speed, the HD Series delivers unparalleled performance in folding and stitching operations.

Full-process Intelligent Control

The key feature of the machine is full computer control, easy operating, stable quality, quick-speed to achieve economic benefits, labor cost saving.

Quick Order Changeover

Job-change can be done in 3-5 mins to do massive production. (Order memorizing function included)

Full Corrugation Compatibility

Suitable for A/B/C/AB flute, 3ply, 5ply, 7ply corrugated paper.

Modular Multi-functional Platform

This machine is an all-in-one machine, separately it can do folding gluing, stitching, or folding gluing and stitching. Single stitching and double stitching can be easily switched.

Smart Stitching Monitoring

The automatic stitch feeding can realize stitch detection and stitch breaking.

Dual-stage Positioning System

Use the paper correction device to make secondary compensation and correct the positioning mistake, eliminate the unaligned part to perfectly stitch the box.

Technical Data

| Model | HD-2800 | HD-2800 Ultra | HD-3600 |

|---|---|---|---|

| Max.Sheet Size(W * L) | 2800mm × 1200mm | 2800mm × 1200mm | 3600mm × 1600mm |

| Min.Sheet Size (W * L) | 830mm × 300mm | 760mm × 300mm | 1160mm × 400mm |

| Max stitching speed | 1600 stitches/min | ||

| Stiching gap | 40-500mm | ||

| Stitching quantity | 1-99 | ||

| Machine net weight | 9.7T | 11T | 12T |

| Machine size | L17000mm × W4100mm × H2200mm | L17000mm × W4100mm × H2300mm | L19000mm × W4400mm × H2800mm |

| Stitch angle | 45° | ||

| Air source | 0.6-0.8Mpa | ||

| Power source | 380VAC/3P, 50Hz | ||

| Power | ≤ 23 KW | ≤ 28 KW | ≤ 31 KW |

| Applicable paper | A, B, C, AB flute, 3ply, 5ply, 7ply corrugated paper | ||

| Automatic feeder pressure adjustment | No | Yes | Yes |

| Automatic stitching head pressure adjustment | No | Yes | Yes |

| Customized small side folding | No | Yes | Yes |

| Folding part full servo contro | No | Yes | Yes |

* This is the current configuration. It may be updated as technology evolves.

Product Gallery

Feeding Part

- With the retention frame pneumatic flap, more stable, higher accuracy.

- Siegling high wear-resistance suction belt, can control the air volume, Ensure complete paper adsorption, ensure stable paper transmission, accurate positioning.

- Split air suction unit, effectively reduce the after-sales maintenance cost and time.

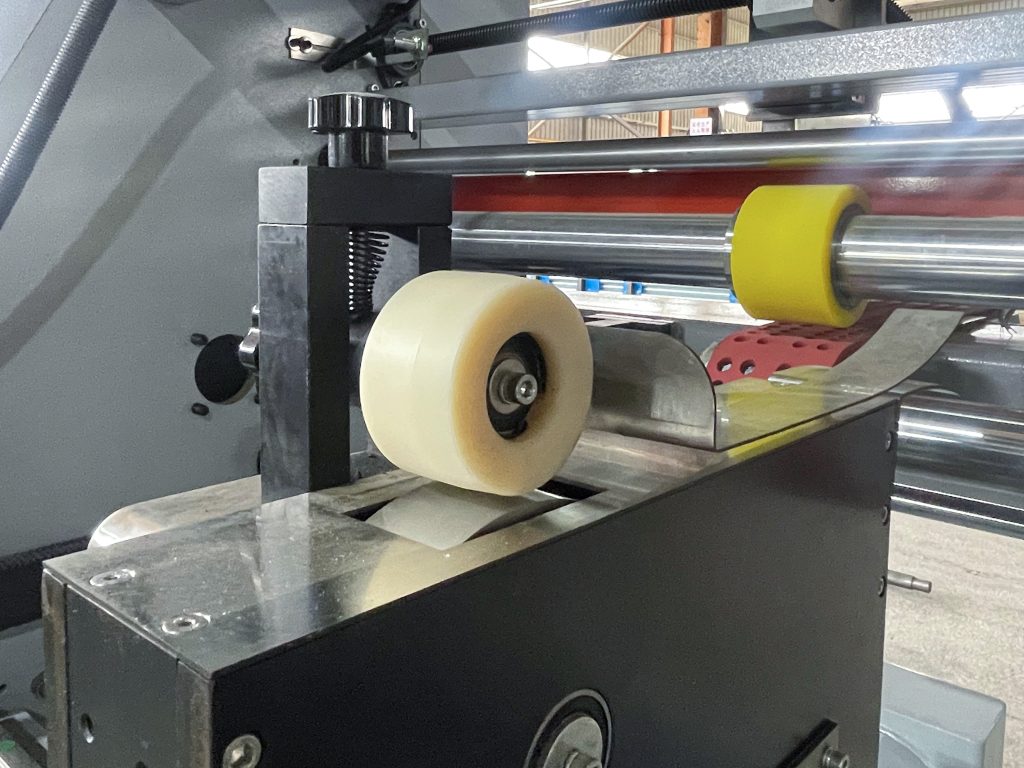

Pressing Part

- The independent edge pressing structure effectively solves the problem of thick cardboard blasting in the process of stitching.

- The split transmission shaft can be adjusted separately and tightened to ensure that the belt pressure is consistent, the paper is stable and effectively avoid the shaft phenomenon.

Creasing Part

- The patented design with active line pressing device to ensure the stability, good forming effect and smooth packing.

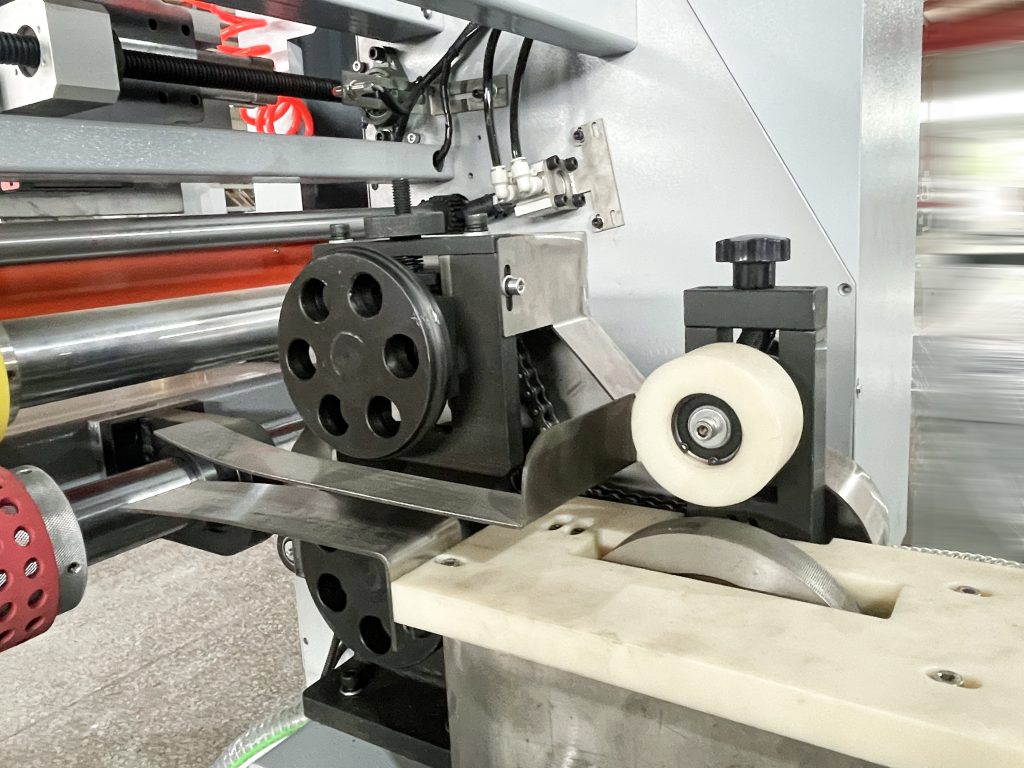

Folding Part

- Adopts synchronous belt drive to avoid the phenomenon of cold start skid and ensure the smooth transmission of paper.

- Reinforced four-axis transmission to ensure that the machine operation, transportation process is stable, no deformation.

Flap Part

- Reciprocating straight line beat correction, high accuracy, stable operation.

- The forward-leaning arched beam is conducive for carton connection and transmission.

- With the sunken belt, greatly strengthen the molding accuracy and smoothness of the carton.

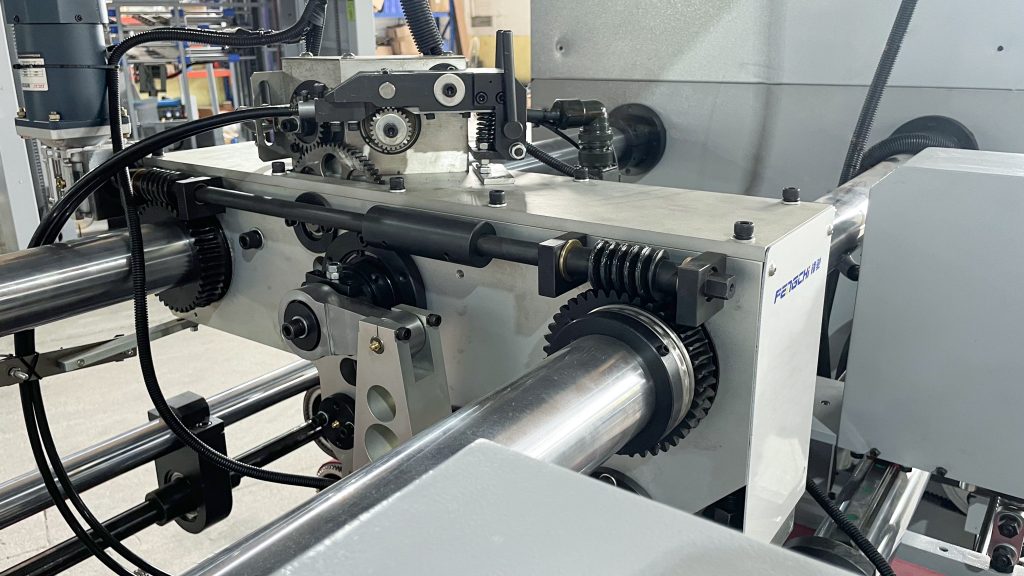

Stitching Part

- The swing stitching head ensures low power consumption, faster speed, and greater stability, enhancing nail box quality.

- Integrated design guarantees precise distance control, while simplifying installation, maintenance, and operation.

- Customized alloy material ensures the blade withstands 6 million cycles wear-free.

- Seven-series aluminum alloy exhibits superior heat dissipation and mechanical properties compared to standard materials.

First Class Service & Support

Fengchi Printing Machinery knows that successful installation, training, and support are critical to your operation and achieving the profitability gains you target. This drives our commitment to your success.

Our goal is to provide you with the tools and technical knowledge that your in-house maintenance needs, to be able to fix their own machines. Our technical support team and parts department work with customers to resolve issues over the phone, but when special care is needed, our team is prepared to make emergency field service visits, to get your plant up and running quickly. Parts, service, and support are handled directly through the Fengchi technical support group.

Trusted by Industry Leaders

See what our customers say about the HD Series folder gluer stitcher.

“The HD Series increased our box production by 40% while reducing labor costs. The quick changeover feature has been a game-changer for our operation.”

– John Smith, Production Manager

“We’ve been using the HD Series for 18 months with zero downtime. The precision and reliability of this machine are unmatched in the industry.”

– Maria Rodriguez, Operations Director

“Fengchi’s support team is exceptional. When we had a minor adjustment issue, they had a technician on video call within 30 minutes to resolve it.”

– David Chen, Owner

Ready to Transform Your Corrugated Box Production?

Join hundreds of satisfied customers who have increased their productivity with the HD Series. Get a quote within 24 hours.

Fill out the form below and our specialist will contact you within one business day.

Contact Form

TEL