Focus Series

Local UV

Glazing Machine

Adds a precise, high-glossy finish to specific parts of your print.

Up to 9000 sheets/hour. Precision ±0.2mm

Focus Series Local UV

Glazing Machine

Up to 9000 sheets/hour. Precision: ±0.2mm

Machine Overview

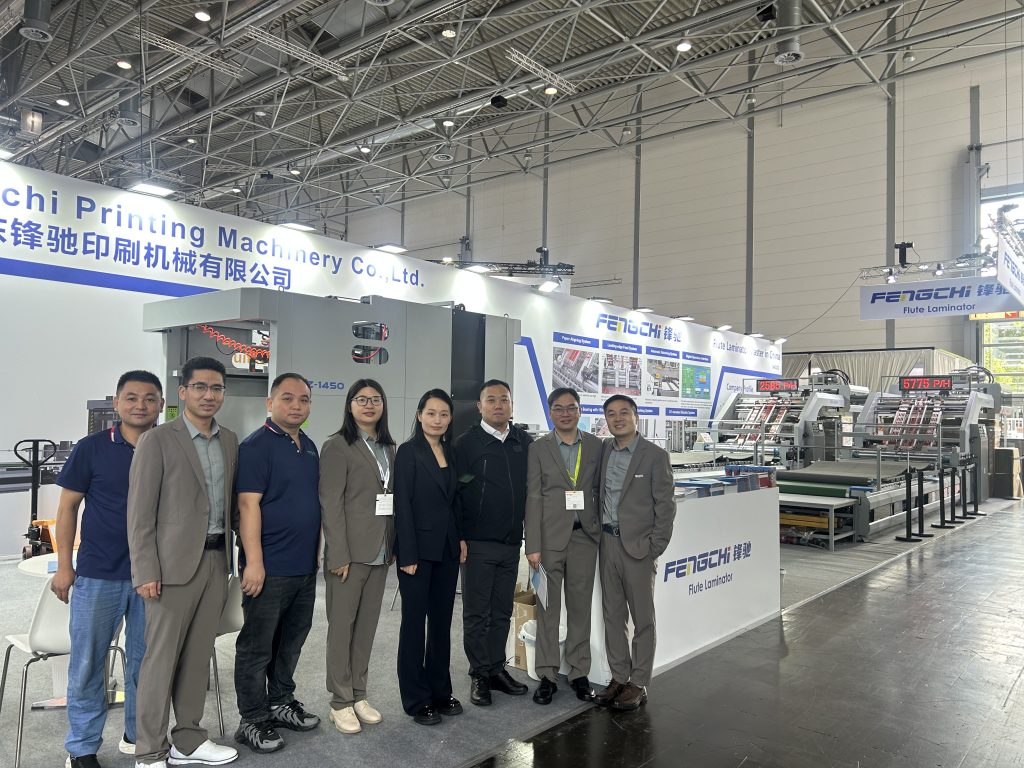

Fengchi is a leading global manufacturer of high-speed local UV glazing machines.

Focus Series High Speed Local UV Glazing Machine adds a precise, high-glossy finish to specific parts of your print, like logos, images or text, creating a strong contrast with matte or uncoated areas.

We guarantee our total support, before, during and after sale and installation.

Key Benefits:

- Precision Spot UV Registration (±0.2mm tolerance)

- Mechanical Velocity: 9000 sheets / hour

- Full Automation: One-Key Operation

- Quick Setup: 2-3 Minutes

Contact our experts to discuss your project or get a quote.

See It in Action

Technical Data

| Model | Focus-105 |

|---|---|

| Max.Sheet Size(L * W) | 750mm×1060mm |

| Min.Sheet Size (L * W) | 340mm×406mm |

| Max.Coating Area (L * W) | 740mm×1050mm |

| SheetThickness | 80~450 gsm |

| Mechanical Velocity | 9000 sheets / hou |

| Machine Dimension | 9050mm ×3150mm ×2350 mm |

| Machine Weight | 11730kg |

| Total Power Required | 48kw Water-based /58kw(uv) |

* This is the current configuration. It may be updated as technology evolves.

Product Gallery

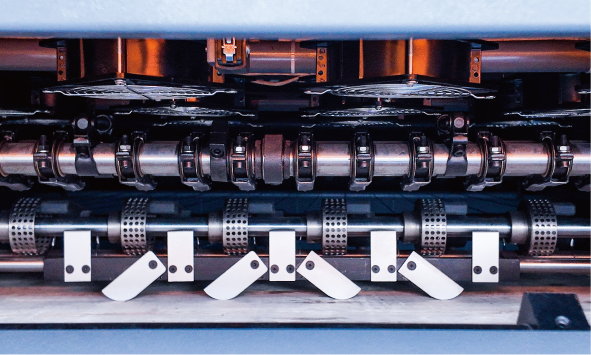

UV Drying System

- Composed of three UV lamp tubes (13kW), reflectors, electrical controls, and cooling/ exhaust equipment.

- Equipped with automatic temperature control and safety controls for overload/ abnormal shutdown.

- Full/half lamp design adjustable to coating speed.

- Operates at full lamp mode normally; automatically switches to half lamp during paper feed tension loss, double sheets, or emergency stop.

Feeder Unit

- High-speed feeder system with maintenance-free suction heads, utilizing single-structure bearing rotation control requiring no lubrication and offering wear resistance. Allows positional adjustment during operation.

- Precise front/side gauges with micro-adjustment for partial color registration.

- Includes Ray-type double sheet detector and missing sheet detector.

- Equipped with paper table lifting safety device.

Delivery Unit

- 16 grippers per gripper bar ensure stable paper transfer.

- Integrated cooling fans and exhaust equipment above delivery stack.

- Vacuum suction paper flattening device prevents warping on thin coated sheets, ensuring flat stacking.

Infrared & Hot Air Drying System

- Designed for water-based coating drying.

- Short-wave infrared system delivers large-area high-efficiency uniform radiation.

- High-pressure hot air system with high thermal efficiency and special air circulation design enables rapid drying.

Multi Function Local Oil Head

- High-reliability suction heads with linear slide rails ensure fast paper feeding, tightly delivering sheets of all sizes.

- Sensitive electro-mechanical double-sheet detector automatically stops feeding upon detecting multiple sheets.

- Maximum paper stack height: 1,150mm.

- Precision front and side guides (front guide and pull guide) with quick-adjust mechanisms for accurate positioning.

First Class Service & Support

Fengchi Printing Machinery knows that successful installation, training, and support are critical to your operation and achieving the profitability gains you target. This drives our commitment to your success.

Our goal is to provide you with the tools and technical knowledge that your in-house maintenance needs, to be able to fix their own machines. Our technical support team and parts department work with customers to resolve issues over the phone, but when special care is needed, our team is prepared to make emergency field service visits, to get your plant up and running quickly. Parts, service, and support are handled directly through the Fengchi technical support group.

Ready to Enhance Your Production Efficiency?

Request a quote or schedule a demo to see the Focus Series in action.