GW-1100L Flute Laminator

GW-1100L — Built for high-volume corrugated lamination

Max speed 15,000 sheets/hour. Accuracy: ±1.5 mm

GW-1100L Flute

Laminator

GW-1100L — Built for high-volume corrugated lamination

Overview

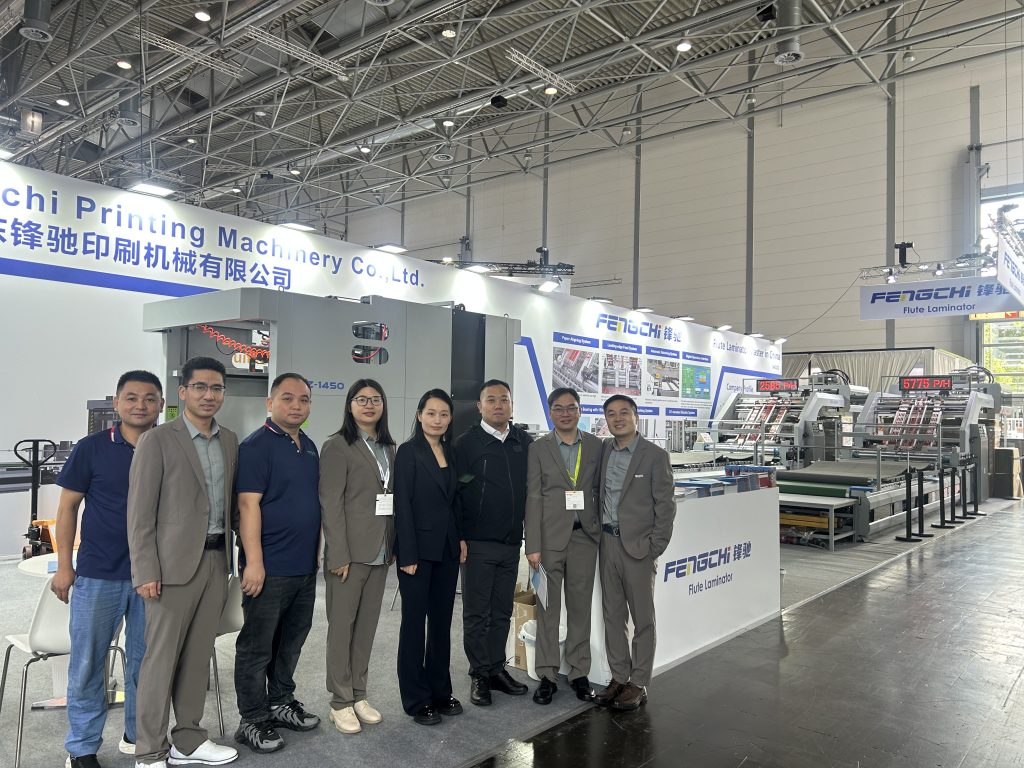

Fengchi is a leading global manufacturer of automatic flute laminators.

The GW-1100L high-speed flute laminators are specifically engineered for reliable, energy-efficient corrugated board lamination processes. They are ideal for packaging manufacturers producing high volumes of corrugated packaging, point-of-sale displays, and laminated cardboard products.

We guarantee our total support, before, during and after sale and installation.

Key Benefits:

- Up to 15,000 sheets/hour

- Accuracy: ±1.5 mm

- Short Setup Times

- Operator Friendly

Contact our experts to discuss your project or get a quote.

End-use Packaging Samples

Case Studies

Spanish Client Case Study

Mexican Client Case Study

Australian Client Case Study

Key Features

Designed for performance, built for durability.

High Throughput

Max speed 22,000 sheets/hr with continuous operation at 16,000 sheets/hr for 24/7 production.

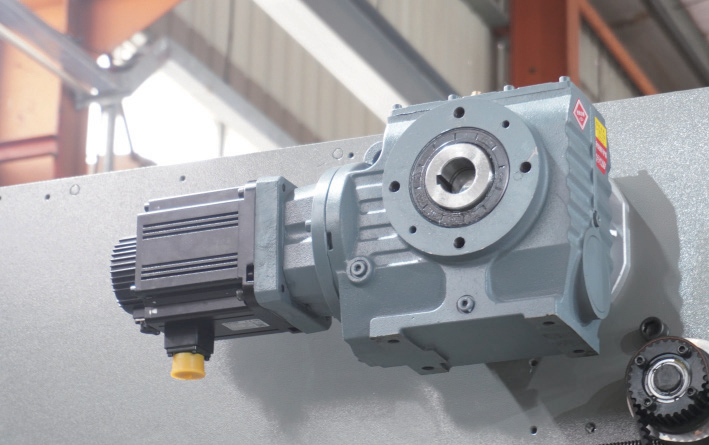

Fully Servo Driven

Full-servo motion control for precise alignment and consistent lamination quality

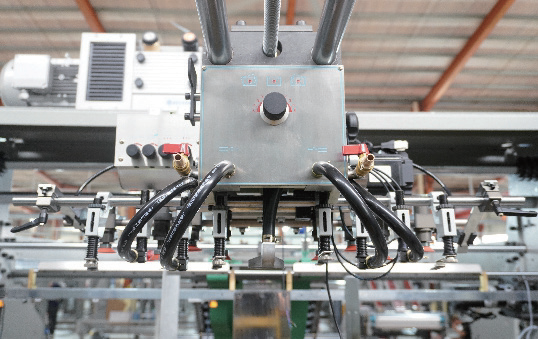

Precise Glue Application

150mm stainless steel roller, laser-engraved anilox roller applies glue evenly at just 18g/m² – 30% glue savings, no splashing, clean finish.

Fast Job Changeover

Quick setup in 2–5 minutes for different batch sizes; boosts production efficiency.

Energy Efficient

Consumes only 8kW/hour – saves up to 20% on power.

Long Lifespan Design

Servo motors and drives built with 35% load reserve for 15+ years of consistent performance.

Your Competitive Advantage

More than a machine, it's a strategic investment.

Maximize Productivity

Increase your throughput and handle larger orders without increasing lead times or labor costs.

Reduce Operational Costs

Lower material waste, reduced energy consumption, and less downtime directly improve your bottom line.

High Quailty

Produce consistently superior laminates with perfect adhesion and a pristine, blemish-free appearance.

Enhance Versatility

Easily handle a diverse range of jobs, from corrugated board to cardboard, on a single machine.

Technical Specifications

Engineered to the highest standards.

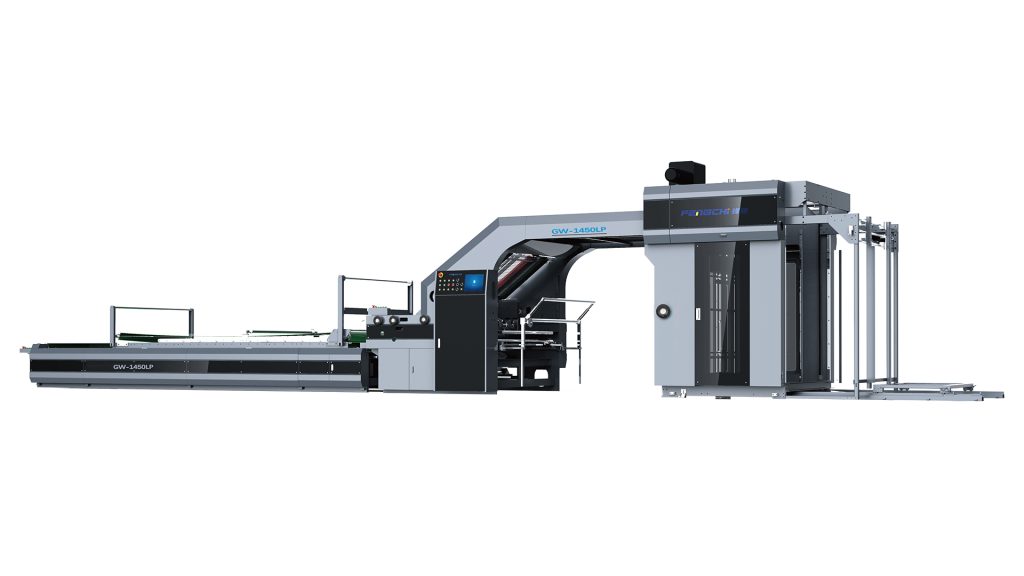

| Model | GW-1100L |

|---|---|

| Max. paper size (W x L) | 1100mm * 1200mm |

| Min. paper size (W x L) | 360mm * 360mm |

| Bottom Paper Sheet Thickness | F flute-10mm |

| Upper Paper Sheet Thickness (W*L) | 150 g-700 g |

| Max. Working Speed | 22,000 Sheets/Hour (175 M/Min) |

| Laminating Accuracy (W*L) | ±1.5mm (Standard Sheet Paper) |

| Applicable Glue | Resin adhesive, starch glue and etc (PH6~8 will be suitable) |

| Power Supply | 380VAC/3P |

| Power | 20KW |

| Applicable paper | Flat corrugated boards (flute types A, B, E, F, double‑wall, etc.) and cardboard weighing ≥ 300 g/m² for lamination |

| Machine weight | 6000KG |

| Overall dimension (L*W*H) | 13600mm * 2000mm * 2550mm |

* The above speeds vary according to paper type.

Product Gallery

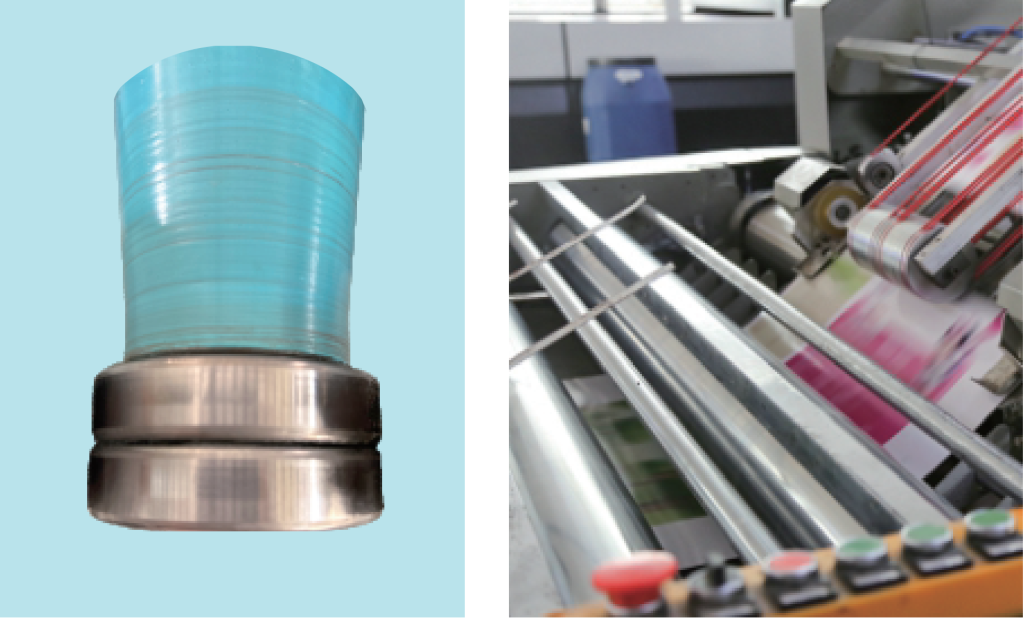

PU Bottom Feeding Wheel

- Unidirectional rotating feeding roller, without wear and tear, service life cycle up to 10 years.

Leading-edge Feed System

- Self-developed leading-edge feed system specially for deformed, warped corrugated papers.

One-button Operation

- Adopting 7-8 servo motors control systems, digital intelligent input, automatic order changeover in 2-3 min.

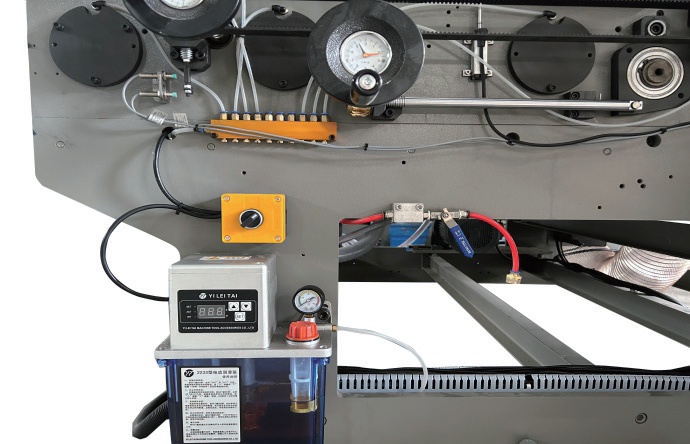

Automatic Lubrication of Bearings

- Intelligent control for automatic lubrication, no need for daily maintenance, saving labor costs, and improving production efficiency.

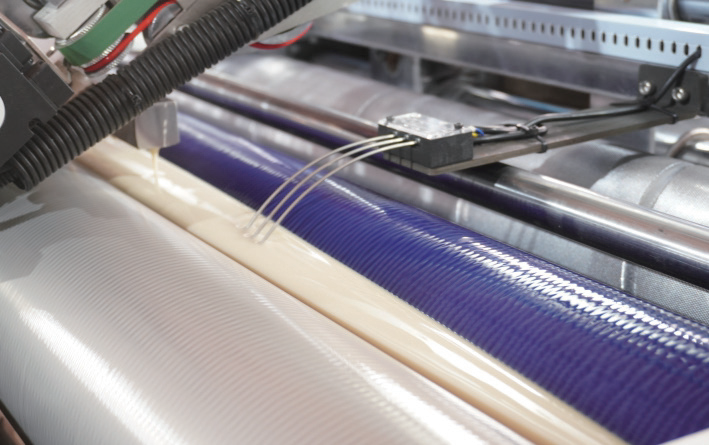

Enlarged Glue Roller

- Enlarged 150mm diameter stainless steel roller, laser engraved anilox, high-speed and stable without glue splashing.

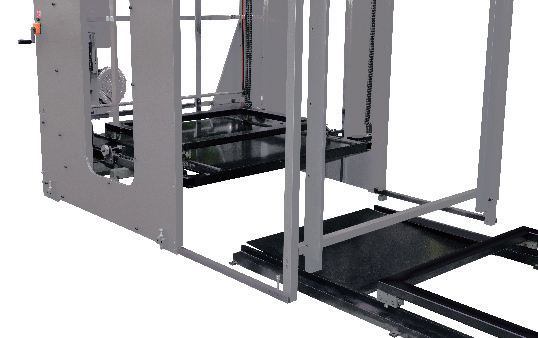

Servo Control Lifting Pile Plate

- High speed feeder smooth feeding, single sheet lifting same as offset printing press, high efficient and stable.

Dual-bearing Structure

- Ensures efficient and stable operation of the machine with doubled life cycle.

Pre-stacking System

- Whole pallet loading platform, saving labor costs and time.

Shaft-less High Speed Feeder

- Servo controlled high-speed shaft-less feeder front-and-rear auto-adjustment.

First Class Service & Support

Fengchi Printing Machinery knows that successful installation, training, and support are critical to your operation and achieving the profitability gains you target. This drives our commitment to your success.

Our goal is to provide you with the tools and technical knowledge that your in-house maintenance needs, to be able to fix their own machines. Our technical support team and parts department work with customers to resolve issues over the phone, but when special care is needed, our team is prepared to make emergency field service visits, to get your plant up and running quickly. Parts, service, and support are handled directly through the Fengchi technical support group.

Ready To Boost Your Packaging Production Efficiency?

Speak with one of our experts today for a personalized consultation and quote.